Case of the Missing Water Tank

Before we finalized the purchase of our boat, we were told via the boat surveyor that our water tank was seriously corroded and should probably be replaced. I guess that makes sense after almost 30 years of the ‘ocean-air’ salty environment. The original tank was crafted out of aluminum, now corroded aluminum. Not the greatest material to hold our drinking water.

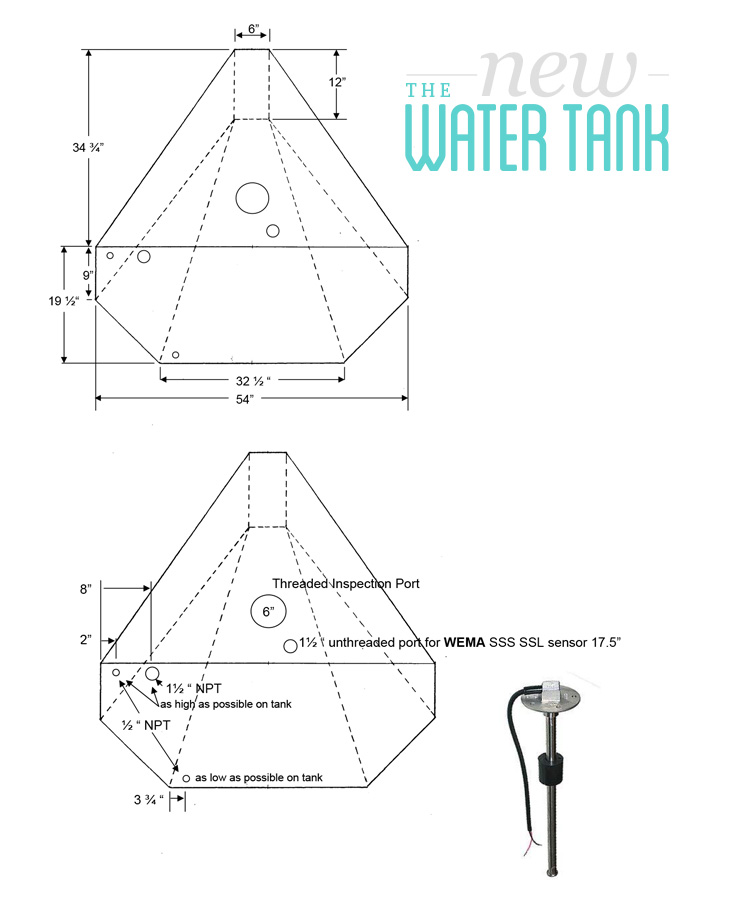

We did some research and decided to order a plastic replacement tank. We didn’t know the exact size / shape that we needed to order, however, so we waited until we were aboard to take final measurements. Well once we got here, we realized that it is WAY more complicated than expected; it is a work of engineering art.

After doing some research on the Island Packet forum, we discovered another gentleman, Bobby, who had an IP-31 and replaced his water tank with a plastic tank. Bobby was very generous in sharing his experience and process, including mapping out the size-specs for the tank, how the old tank was removed, and how the new one installed. We found a pot o gold (or fresh water!)

We contacted the fabricator that Bobby used, Dura-Weld, and sent them our (his) measurements for the new tank. They let us know it would be about 5-6 weeks until we could expect to see it in the mail, so we let ourselves put the project off for awhile. It felt daunting at the time to remove the old one, redo all the plumbing (which looks like a nightmare) and install the new one properly. I guess if you have extra cash, you can pay professionals to do this, but we are pretty sure we can figure it out ourselves…we’re smart right?

So the first part of this 3-step process is the removal of the old tank. Our old tank is a 70-gallon beast. It lives in the lockers at the very bow of the boat, aka, V-berth (and our bedroom). We knew what to expect because Bobby (and a few others) talked about their experiences and shared what they had to do to remove the old one. First things first, we have to remove all the old plumbing fittings from the old tank.

Jill and I took turns pulling off old hose clamps on various hoses (not quite sure what they all were for) any and all screws holding the tank down and any other reachable and removable extremity. It took most of the morning, but all hoses, mounts, water gauge and fittings were apart, labeled and set aside (so we could put them back together).

Okay, now what? Well I guess we knew what was next, but were NOT looking forward to it. From our research, we learned that we have to cut off a large chunk from the bottom of the tank to get it out of the V-berth doorway. So with a quick trip the hardware store for extra blades and a spare tarp, we walled off the ‘cutting area’ (so aluminum shrapnel would be kept as confined as possible). Jill and I had to flip the tank up for relatively-easy access. We drew the area that needed to be cut (or that we thought needed to be cut). Then there was nothing left to do but start cutting.

I HATE CUTTING METAL…it is terrifying. I had to wear full-protective gear so I was covered head to tow. It also happened to be about 90-degrees in the boat and in a confined space that felt like a cave, It was probably even hotter. Even though I did have to cut the holding tank, this tank is much ticker and larger. But I couldn’t stall any longer, so I went for it.

It was LOUD. REALLY LOUD. I didn’t have the foresight to put in earplugs but Jilly said she had to leave the boat because it was so loud and could hear it on the other side of the marina. After 20-30 minutes, with only one saw break and a few battery changes, I finished cutting the section (thank god!)

Jilly came back in and took over cleaning things up – mostly shards of aluminum (which were everywhere). Once relatively clean, we tag-teamed the tank and tried to lift it out of the doorway. After some battering around we realized that it was still too big. Dangit! So I had to gear up for metal-cutting-torture part 2.

Side note: when boats are constructed, their tanks are often put down before floors, walls or cabin-tops, so it is VERY normal to have to cut things apart to remove them.

So I went at it again, this time making 100% sure that it was going to fit through the door (I’m never doing this again so I was darn-sure!). Jilly came back and cleaned AGAIN and then we went at it. This time we had no problem getting the tank out of the locker, doorway, companionway and then out into the cockpit. A passerby helped us get it off our boat and onto dock, where we rolled it to its grave…aka…the dumpster.

One of the greatest things about living aboard is the sailing community is SO FRIENDLY. Our buddy, Dan (s/v Clyde), stopped by right before dinner to visit. He had dinner plans with another liveaboard Dom, so we decided to join in and share our meal with them. It was like a potluck where everyone brought something and we all shared. Super tasty, super fun. Afterwards Dan bought us dessert, brownies and ice cream which we all shared on Dom’s boat. It was a really nice way to celebrate the success of the case of the missing water tank

wow! Another really difficult project conquered. You guys are amazing! I hope getting the new tank in is much easier!

Hello Jake and Jill, Wow! Your project achievements as well as your never ending list of to-dos is just amazing. Ha! Of course the water tank is key. I was surprised to learn that the ideal replacement for your metal tank was….another metal tank. Is this accurate? It seems like an inflatable plastic bladder (think well designed water bed) would be more suitable for this application and for easy in and out maintenance and repair as well as air tight closure, as well as corrosive resistance to salt water/air. But then again, this was a land lovers intuition.

I hope your motor is on the mend.

Always with My Best,

Rob

Thanks! The replacement tank is a plastic tank (not metal). But yes they do make inflatable bladder “tanks” and many boaters swear by them. For us there is too big a risk of popping (they tend to not do so well in larger sizes). We took a wonderful vacation away from the boat for a few days and I think its exactly what we needed. Now just need some luck and all of our spare parts to come in and hopefully we can get the new tank in, the engine up and running, and be on our merry way! Miss you guys.

Jake & Jill

Nice work removing the water tank. We had to remove our old tank too, but luckily it had pretty easy access under the floorboards near the companionway. We did have to cut a little chunk off to get it out of the doorway, but not near as much as it looks like you had to. Aluminum gets everywhere once its cut. Hopefully you didn’t get any in your bilge. We weren’t so careful and had some issues down below, but thankfully nothing major. Nice website.

We were as careful as could be, but our tank-area up front offered much more opportunity to keep things from flying everywhere. Isn’t cutting metal scary? I guess its not if you are used to it, but I hope to never have to do that again! Thanks for reading.

Thanks for reading.